Are you facing constant production delays or high scrap rates with your neon flex? Many factory owners focus only on motor power while ignoring the complex internal flow of the extrusion mold.

To succeed with an LED silicone strip extrusion machine, you must master the precision of the mold design and manual tuning. A perfectly adjusted mold ensures balanced material flow for three-color co-extrusion, prevents internal air gaps, and guarantees the 16mm x 15mm dimensions required for high-end architectural lighting.

I have spent over five years as a sales engineer in this industry. I have traveled to Saudi Arabia, Russia, Poland, and Vietnam to set up these production lines. I often see customers who buy a great machine but cannot make a good product because they do not understand the “soul” of the mold. In my experience, the machine is the body, but the mold is the heart. If the heart is not tuned correctly, the body will never run at full speed. I have two sons, and I tell them that precision matters in everything you do. This is especially true for silicone extrusion.

How does the 1615 three-color mold define your LED silicone strip extrusion machine performance?

Are you struggling to get a clean separation between colors in your neon strips? If your white base is bleeding into your transparent top layer, your mold pressure is likely out of balance.

The 1615 core mold for an LED silicone strip extrusion machine is designed to manage three distinct material feeds simultaneously. It uses a high-grade S136 steel core to guide the 12mm LED board while ensuring the silicone flows evenly around the electronics without causing mechanical displacement or electrical failure.

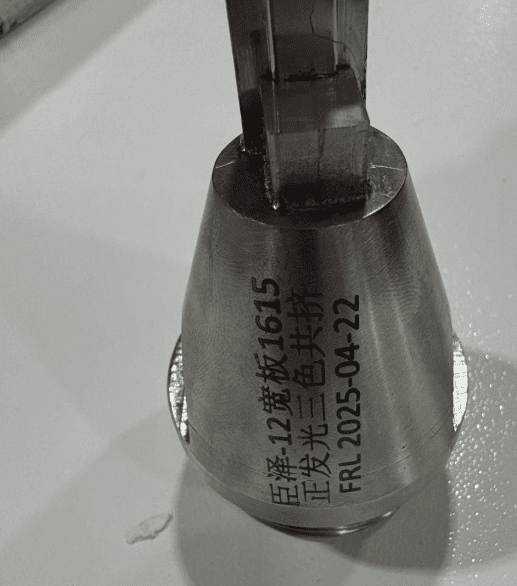

When I was working at a factory in Poland last year, we looked at a mold dated April 22, 2025. This was for a 1615 front-emitting strip using a 12mm board. The complexity of this design is hidden inside the steel plates. You can see the internal channels where the silicone travels. If one channel is even 0.1mm too tight, the material will back up. This creates a “pulsing” effect on your conveyor belt. I used my knowledge of CNC processes to help the local engineers understand why the flow was uneven.

I like to visit different factories because every production environment is unique. In Russia, the cold workshop temperatures change the viscosity of the silicone. This means the LED silicone strip extrusion machine must be calibrated differently than in a hot Saudi Arabian factory. I often stay on-site for 7 to 14 days to solve these problems. I don’t just sell you the hardware. I help you master the process. I have seen many engineers like David from India who have a great mechanical background but need help with the specific “rheology” of silicone.

Technical Specifications for 1615 Production

| Parameter | Standard Requirement | Impact on Quality |

|---|---|---|

| Core Material | S136 Hardened Steel | Prevents wear from high-pressure flow. |

| Board Width | 12mm Precision Slot | Ensures LED strip stays centered. |

| Co-extrusion Layers | 3 Colors (Base, Side, Top) | Provides the “Neon” light diffusion effect. |

| Precision Tolerance | +/- 0.05mm | Necessary for installation in aluminum profiles. |

I enjoy reading about economics and politics. It helps me see how the global lighting market is moving toward more complex, custom-shaped strips. A standard 1615 mold is just the beginning. I tell David that he must provide clear drawings of his LED strip samples. Every brand of silicone has a different performance level. If he buys material locally in India, we must test how it flows through our LED silicone strip extrusion machine. This is a huge work to confirm every detail. But it is the only way to meet the competition in the market.

Why is manual mold modification the most critical skill for your machine operators?

Do you think a brand-new mold should work perfectly right out of the box? In reality, even the best CNC-machined mold usually requires a technician’s “human touch” to achieve perfect flow.

Manual mold modification involves using a high-speed sanding tool to slightly widen material paths and balance pressure. This adjustment is essential for an LED silicone strip extrusion machine because it compensates for small variations in silicone viscosity and barrel pressure that computer simulations cannot predict.

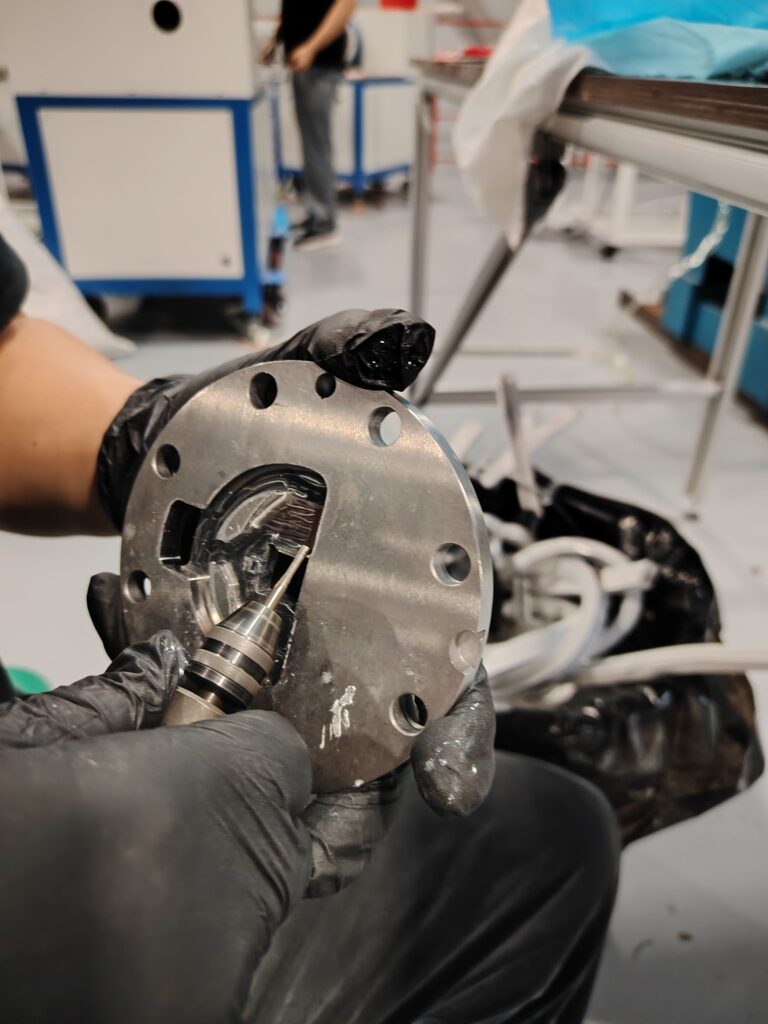

Look at the photo where the technician is using a small rotary tool. He is not fixing a mistake. He is “tuning” the flow. I have done this many times in Saudi Arabia and Iran. We start the LED silicone strip extrusion machine and look at the first few meters of output. If the bottom of the 1615 strip is too thin, we need to “increase material feeding” to that specific section. We take the mold apart and sand the inner path to make the gap bigger.

This is where my experience with hardware processes and surface treatment becomes useful. You cannot just sand randomly. You have to understand where the pressure is too high. I have two sons, and I teach them that you have to listen before you act. The machine “speaks” through the quality of the strip. If the strip looks wavy, the mold is resisting the material. We use a sanding tool to smooth the path. This reduces friction. Less friction means the silicone moves faster and smoother. This is the secret to 24/7 production success.

Why manual tuning is better than pure automation

- Real-world compensation: It accounts for the actual temperature of your workshop.

- Material flexibility: It allows the same mold to work with different brands of silicone.

- Flow optimization: It ensures that the white opacifying edge and the transparent top meet perfectly.

When I visit factories, I spend a lot of time training the local staff on this skill. It takes 7-14 days because it is an art. You have to “feel” the metal. I often play basketball on the weekends, and I think of it like a jump shot. You need the right technique, but you also need the right feeling. If your staff can modify their own molds, you save thousands of dollars. You don’t have to wait for a technician to fly from China every time you change your material supplier. This is the kind of technical support that ensures your long-term success.

How to troubleshoot common defects in your LED silicone strip extrusion production?

Are you seeing cracks, gaps, or uneven edges on your final neon flex products? These defects are usually the result of a mismatch between your machine settings and your mold configuration.

To solve production defects like material gaps or uneven opacifying edges, you must check the synchronization between your LED silicone strip extrusion machine and the mold temperature. Most defects are caused by “uneven silicone material extrusion,” which can be fixed by cleaning the die head and re-aligning the internal core.

I have seen many types of defects in different countries. In Vietnam, a customer had a problem where the silicone was not sticking to the LED strip properly. We call this a “material gap.” It usually happens because the vacuum pump is not strong enough or the mold is too cold. I also see “uneven silicon material extrusion bottom defects” in many startup factories. This happens when the mold is dirty. You can see the photo where we use a scraper to clean the residual silicone. You must be very careful not to scratch the mirror finish of the S136H steel.

I always tell David that he needs to keep a logbook of every production run. If the “opacifying edge” is not even, it means the three-color co-extrusion balance is off. We look at the cross-sectional shape detection. We use a digital caliper to check the dimensions. In one of our tests, the width was 16.28mm. This is slightly over the 16mm target. We had to adjust the cooling tank speed on the LED silicone strip extrusion machine. If the conveyor pulls too fast, the strip becomes thin. If it is too slow, the strip becomes fat.

Common Defects and Solutions

| Defect Type | Likely Cause | Solution |

|---|---|---|

| Internal Air Gaps | Material feeding pause | Take care of material feeding,especially when manual feeding |

| Color Bleeding | Pressure imbalance | Modify the material path to balance flow. |

| Dimensional Error | Conveyor speed mismatch | Synchronize the puller speed with the screw RPM. |

| Surface Ripples | Dirty mold path | Disassemble and clean the mold plates thoroughly. |

I like hiking because it requires patience. Troubleshooting an LED silicone strip extrusion machine is the same. You cannot rush it. You must change one variable at a time. First, check the material. Then, check the temperature. Finally, check the mold. I have the experience to solve any problem from the manufacture of the machine to your factory floor. I know the international business practices well, so I can explain these technical issues in simple terms for your team.

Why is regular mold cleaning and maintenance the key to continuous production?

Is your production line stopping every few hours because of “burnt” silicone or clogs? If you do not have a strict maintenance schedule, even the best LED silicone strip extrusion machine will fail.

Regular maintenance of your LED silicone strip extrusion machine mold involves complete disassembly and removal of residual silicone using specialized cleaning tools. This process prevents “dead zones” where silicone can over-cure and cause surface defects on the finished neon flex, ensuring high optical quality and consistent dimensions.

Look at the photo of the “inner extrusion mold clean.” We are removing white silicone residue. If you leave even a small piece of old silicone inside, it will act like a dam. It will block the flow of the new material. This causes the “uneven edge” problems that I discussed earlier. I recommend a deep clean every 7 to 14 days of continuous production. When I train teams in Saudi Arabia or Russia, I make sure they know how to take the mold apart safely.

I have a strong interest in politics and economics, and I see how the cost of labor is rising globally. This means you cannot afford to waste time on maintenance mistakes. You need a fast, efficient process. My machines are designed with a modular mold system. This makes it easier to disassemble. I have years of experience with hardware processes, so I know how to make tools that last. I provide my clients with a full set of maintenance tools and a detailed manual. But more importantly, I provide the training so your workers can do it right the first time.

The 3-Color Maintenance Checklist

- Visual Inspection: Look for scratches on the mold exit.

- Channel Cleaning: Use a soft scraper for the internal paths.

- Bolt Tightening: Ensure the plates are sealed to prevent pressure leaks.

- Lubrication: Keep the LED silicone strip extrusion machine drive system smooth.

I have visited hundreds of factories. The most successful ones are the cleanest ones. I tell David that his R&D team must work closely with the production team. If the design is too complex, maintenance becomes a nightmare. We find the balance between product function and manufacturing reality. This is how we realize the product function while keeping the costs low. Choosing the right technical partner is about finding someone who knows the machine and the material.

How to achieve a “Perfect Shape” and win the market with your LED products?

Are you ready to stop making “average” products and start making “premium” neon flex that sells for a higher price? The difference between a cheap strip and a high-end one is found in the final millimeters of the extrusion process.

To achieve a perfect shape with your LED silicone strip extrusion machine, you must ensure that the strip exits the mold and hits the conveyor belt with zero tension. This requires a perfectly balanced 1615 mold and a cooling system that cures the silicone at the exact moment it reaches its final dimensions.

When you see a “perfect shape get off from conveyor belt,” it is a beautiful sight. The edges are sharp. The colors are distinct. The surface is smooth. This is the result of everything working together: the LED silicone strip extrusion machine, the high-viscosity silicone, and the tuned mold. I have helped customers in Poland and Vietnam reach this level of quality. It makes me proud when I see their products installed in big shopping malls or city facades.

I am a sales engineer, but I am also a creator. I have experience with surface treatment and CNC. I know what it takes to make a product look professional. I have two sons, and I want to show them that being a specialist is valuable. In the LED market, there are many options. Different brands of silicone have different prices and performances. I help you choose the right material for your quality level. I can solve any problems from manufacture to your factory. If you want to achieve success, you need an authentic solution, not just a cheap machine.

Final Inspection Benchmarks

- Dimension Check: Use digital calipers to verify 16.00mm width.

- Light Diffusion: Ensure no “hot spots” are visible through the top layer.

- Adhesion Test: Try to pull the layers apart; they should be fused as one.

- Flexibility: The strip should bend easily without cracking the outer skin.

I often think about the future of this industry. As economics change, the factories that can produce high-quality “neon” light output with low scrap rates will be the winners. I am here to provide the machine proposal, the quotation, and the 7-14 days of on-site support to make that happen. From China to your factory, I am your partner for success. I can provide the silicone and additives from different factories if you cannot find them locally. I do the huge work of confirming every detail so you don’t have to.

Mastering your LED silicone strip extrusion machine is about combining precision technology with manual expertise. With the right mold and training, your factory will achieve production excellence.