Your LED strips fail. Colors are inconsistent. Curing times vary wildly. The problem often starts long before the extrusion machine.

Precision silicone rubber compounding is the invisible foundation of successful LED strip extrusion. An inconsistent or poorly refined compound leads directly to defects, waste, and unreliable products. Mastering material preparation is the first step to manufacturing excellence.

At SiliconExtrusionTech, we know the extruder is only as good as the material you feed it. I’m Eason, and I’ve spent countless hours in material labs and mixing rooms worldwide, troubleshooting problems that began with a poorly mixed batch. This article breaks down the critical, often-overlooked science of silicone rubber compounding for LED strips. Understand how material quality impacts your final product.

Chapter 1: Why Do Raw Material Selection and Storage Matter So Much?

A perfect mix is impossible if your starting ingredients are compromised from the moment they arrive.

The journey to a perfect compound begins with correct material sourcing, handling, and storage. Improper practices here introduce variables that no mixer can correct, leading to batch failure and costly production stops.

Think of your raw materials as delicate ingredients for a complex recipe. Each one has specific requirements. Ignoring them guarantees problems down the line. We manage this through a disciplined, three-part system.

Part 1: Sourcing and Qualifying Materials

Not all silicone polymers or additives are equal. A cheaper base polymer might save cost upfront but cause extrusion instability or poor adhesion. I work with clients to qualify materials. We often run small trial batches to test a new supplier’s silicone compound before committing to a bulk order. For key additives like platinum-curing agents, we recommend trusted brands to ensure consistent catalytic activity. The goal is to lock in a reliable supply chain, not just find the lowest price.

Part 2: The Critical Role of Storage

This is where many factories make simple, expensive mistakes.

- Silicone Base Polymer: It must be stored in a cool, dry place. Heat and moisture can begin premature cross-linking or change its viscosity.

- Additives: This is even more crucial. Diffuser agents like titanium dioxide must be kept perfectly sealed to avoid moisture absorption, which causes clumping. Platinum catalysts are highly sensitive. We insist they are stored in their original, sealed containers, often in a temperature-controlled cabinet or even a dedicated refrigerator. I’ve seen entire batches ruined because a catalyst bucket was left open in a humid room.

- Organized Inventory: We implement a “first-in, first-out” system. Old stock gets used first. Every container is clearly labeled with the material name, batch number, and arrival date. This traceability is essential for troubleshooting.

Part 3: Controlled Dispensing Environment

We set up a dedicated area for weighing and dispensing. This area is clean, well-lit, and free from contaminants like dust from other production processes. The weighing scales are placed on stable, vibration-free tables. This controlled environment is not a luxury; it’s a necessity for achieving the precision your LED strip extrusion process demands. A speck of foreign material or a few grams of inaccurately weighed additive can alter the cure time, color, or optical properties of an entire production run.

Getting these foundational steps right eliminates a huge range of potential defects. It transforms material preparation from a chaotic chore into a repeatable, scientific procedure. Learn about our material sourcing support for your project.

Chapter 2: What Are the Essential Steps in the Silicone Compounding Process?

Mixing silicone is not like stirring paint. It is a multi-stage, precision process where sequence and technique are everything.

Effective silicone rubber compounding follows a strict sequence: precise weighing, primary polymer breakdown, controlled additive incorporation, and thorough homogenization. Skipping or rushing any step compromises the entire batch’s performance.

The compounding process is a physical and chemical transformation. I train teams to see it as four distinct, controlled phases.

Phase 1: Precision Weighing

This is the most critical step. Every ingredient for the batch is weighed separately on a calibrated digital scale. The amounts are not estimated; they are calculated to exact ratios from the formulation sheet. For a platinum-curing agent, the tolerance might be within 0.1 grams. We use clean containers for each ingredient to prevent cross-contamination. The formula sheet is checked and double-checked before any material is added to the mixer.

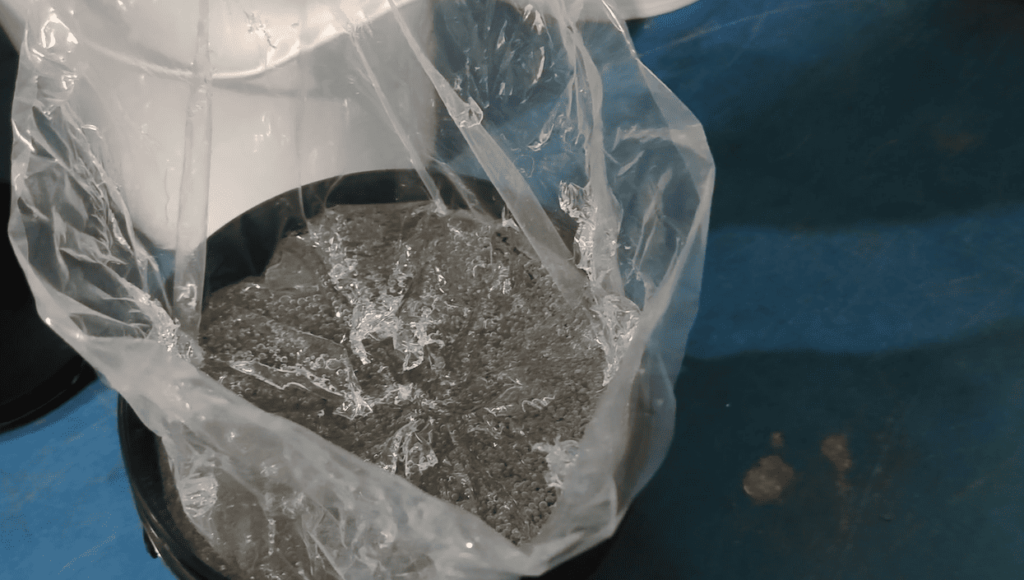

Phase 2: Primary Mixing and Polymer Breakdown

The base silicone polymer (often a thick gum) is loaded into the mixer first—usually an internal mixer or a dual-rod kneader. The machine’s mechanical shear begins to plasticize the polymer, breaking down its structure and making it receptive to additives. This phase establishes the compound’s base workability.

Phase 3: Controlled Addition of Additives

Additives are not dumped in all at once. They are added in a specific order, often dictated by their function and compatibility.

- Fillers and Diffusers First: Inert materials like titanium dioxide (TiO2) for diffusion or other fillers are added early. This allows maximum time for dispersion.

- Performance Additives Next: Other additives like adhesion promoters or thermal conductors are added.

- Catalyst LAST: The platinum-curing agent is always added at the final stage, after the compound has cooled down sufficiently. Adding it too early or when the batch is too hot can cause “scorch”—premature curing inside the mixer, which ruins the entire batch.

Phase 4: Refining and Homogenization

After the internal mixer, the compound is usually transferred to a two-roll mill. This is where true refinement happens. The operator feeds the rubber through the rotating rolls, which exert tremendous shear force. We use a skilled technique: cutting the band of material with a knife and folding it back onto itself. This “cut and fold” action is repeated dozens of times. It does three things: it evenly distributes the additives down to a microscopic level, it further breaks down the polymer for smoother extrusion, and it removes entrapped air. The operator judges readiness by the compound’s appearance—it should have a uniform color and texture with no streaks or granules.

This disciplined process turns a collection of raw materials into a homogeneous, predictable engineering material. It is the bedrock of consistent silicone rubber extrusion. Without it, you are not manufacturing; you are gambling with every batch.

Chapter 3: How Do We Validate and Troubleshoot a Silicone Compound Batch?

A mixed batch is not a good batch until it passes validation. How do you know it will perform in your extruder?

Batch validation involves physical tests and small-scale trials to confirm key properties like cure time, color, viscosity, and final elastomer performance. This proactive step prevents large-scale production failures and material waste.

Validation is our quality gate. We never assume a batch is good. We prove it. This process follows a clear “Test, Analyze, Confirm” loop.

The Core Validation Tests

For every production batch, we take a small sample and run a series of checks.

- Visual and Tactile Inspection: Does the color match the standard? Is the texture smooth and uniform, or are there undispersed particles or streaks? We feel it for consistency.

- Cure Characteristic Test: This is the most important test. We use a rheometer or a simple cure meter. A small piece of compound is heated, and the machine graphs how it cures. We check two things: the scorch time (how long before it starts to cure, which affects processing safety) and the full cure time. If these times are outside the specification, the batch will cause havoc in the curing oven, leading to under-cured or over-cured strips.

- Physical Property Test (for key batches): We may create a small cured plaque and test its hardness (Shore A), tensile strength, and elongation. This confirms the final elastomer will have the right flexibility and durability for an LED strip.

- Trial Extrusion Run: The ultimate test. We run a few kilograms of the new batch at the start of the production line. We examine the extrudate: Is the surface smooth? Is the shape stable? Does it adhere properly to the test PCB?

Troubleshooting Common Compound Defects

When validation fails, we diagnose the root cause. I use a simple checklist based on the symptom:

- Problem: Inconsistent Cure Time.

- Check 1: Was the platinum-curing agent weighed accurately and from a fresh, active batch?

- Check 2: Was the batch temperature in the mixer too high, causing partial catalyst deactivation?

- Check 3: Is there contamination from a previous batch?

- Problem: Poor Color or Diffusion Uniformity.

- Check 1: Was the diffuser agent (TiO2) properly dispersed? This usually points to insufficient refining time on the two-roll mill.

- Check 2: Was the color masterbatch added in the correct sequence and fully mixed?

- Problem: High Viscosity or Scorch.

- Check 1: Did the compound overheat during mixing? Check mixer cooling.

- Check 2: Was the catalyst added too early while the batch was still hot?

By validating every batch, we turn compounding from a black art into a controlled science. It gives the extrusion team the confidence to run at full speed, knowing their material is perfect. This discipline saves thousands in wasted silicone and lost production time.

Chapter 4: How Does Expert Compounding Drive Your Overall Production Success?

Superior compounding doesn’t just make good material; it makes your entire factory more efficient, profitable, and competitive.

Investing in expert silicone compounding delivers clear ROI: it reduces extrusion defects, minimizes material waste, standardizes cure cycles for faster throughput, and ensures your final LED strips have consistent, high-quality performance that builds your brand reputation.

The benefits of mastering compounding cascade through every stage of your operation. Let’s look at the direct impact.

Impact 1: Dramatic Reduction in Extrusion Line Problems

A consistent, well-refined compound behaves predictably in the extruder. It flows evenly through the crosshead mold, maintaining a stable pressure. This directly reduces defects like:

- Variation in Wall Thickness: Caused by unstable material viscosity.

- Surface Defects (Sharkskin): Often linked to poor polymer breakdown or additive dispersion.

- Adhesion Failure: Can be traced to incorrect additive levels or contamination in the batch.

When these defects disappear, your line runs smoothly. You spend less time adjusting the machine and more time producing good product.

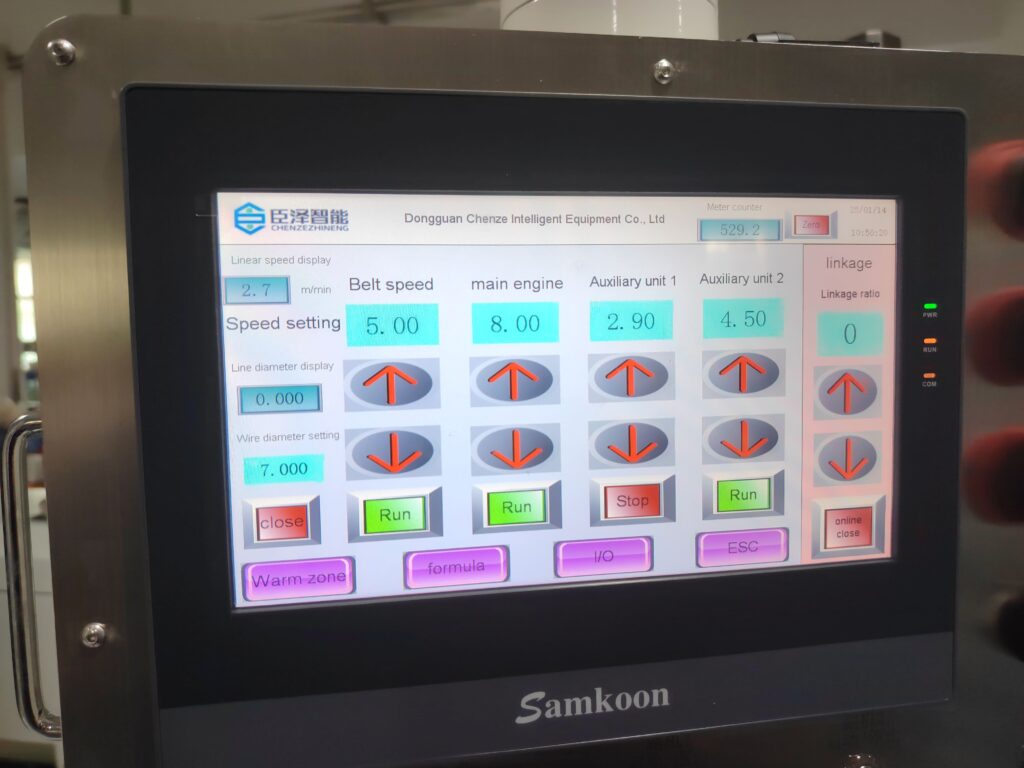

Impact 2: Optimization of the Entire Production Cycle

A validated compound has a known, precise cure time. This allows you to scientifically set your curing oven temperature and conveyor speed. You are no longer guessing or running too slow to be safe. You can optimize for the fastest possible cycle time that still guarantees a fully cured strip. This increases your production capacity from the same equipment. It also saves significant energy in the curing oven.

Impact 3: Long-Term Supply Chain Stability and Cost Control

When you have a locked-down, reliable compounding process, you gain leverage and stability.

- You can qualify alternative material suppliers with confidence, because you have a robust test protocol to ensure they meet your standard.

- You reduce batch-to-batch variation, which means you use less material in trial runs and produce less scrap.

- Your product quality becomes a trademark. Customers receive the same high-performance LED strip, order after order. This builds trust and allows you to command a premium price.

In my projects, the clients who focus on compounding from day one are the ones who achieve profitability fastest. They aren’t fighting daily fires on the extrusion line. Their teams are confident. Their output is reliable. They see silicone rubber compounding not as a cost center, but as their core competitive advantage. It is the smartest investment you can make in your LED strip manufacturing business.

Conclusion

Precision in silicone compounding is not optional; it is the fundamental prerequisite for predictable, profitable extrusion. It transforms raw materials into a reliable engineering asset.

Struggling with inconsistent batches, extrusion defects, or unpredictable cure times?

The solution starts in your mixing room. I can help you audit your current process, implement precise weighing and refining protocols, and establish validation tests that prevent waste. Let’s build the material foundation your high-quality LED strips deserve.

Contact me, Eason, for a consultation on your silicone compounding process. Let’s mix success, from the first gram to the final strip.