Machines sitting idle and high material scrap rates will destroy your factory’s cash flow. You need more than just a delivery; you need a system that works from day one.

Success with an LED silicone strip extrusion machine depends on expert on-site commissioning and staff training. This process reduces startup waste by up to 40% and ensures that complex multi-layer co-extrusion molds are perfectly calibrated for long-term, high-speed production in any local environment.

I have spent more than five years as a sales engineer in this industry. I have installed these machines across the globe, from the cold winters of Russia to the heat of Saudi Arabia. I know that a machine is only as good as the person operating it. You can explore our full range of LED silicone strip extrusion machine solutions to see the technology we bring to your floor.

How can 7-14 days of expert training transform your LED silicone strip extrusion machine into a profit center?

Are your workers struggling to understand the delicate balance of silicone pressure and heat? Without proper training, your expensive equipment is just an oversized heater that wastes expensive raw materials every hour.

Expert training for an LED silicone strip extrusion machine bridges the gap between mechanical delivery and actual production. A 7-14 day intensive program teaches your team to master mold synchronization, material feeding, and real-time troubleshooting, turning raw silicone into high-value, salable neon flex products immediately.

When I travel to places like Poland or Vietnam, I don’t just stay in a hotel. I stay on the factory floor with the workers. I have two sons, so I know that patience is the key to teaching new skills. An LED silicone strip extrusion machine is a very complex tool. It involves PLC systems, precise temperature zones, and high-pressure extruders. I have seen many engineers like Shane from the USA who are very smart in product design but have never touched a silicone screw. I take the time to explain the “why” behind every setting.

I remember a project in Russia where the local staff was very skilled in mechanics but new to silicone. I used my knowledge of CNC processes and hardware to explain how the mold plates fit together. We spent 10 days focusing on the “startup sequence.” If you start the machine in the wrong order, you will clog the die head. That costs hours of cleaning time. By the time I left, their team was able to start production in under 30 minutes with almost zero scrap. This is why I always bring an electronic engineer with me. We make sure the “brain” and the “body” of the machine are perfectly in sync. You can read more about our technical support services here.

The Impact of Professional Training on Factory Metrics

| Training Phase | Skill Acquired | Production Benefit |

|---|---|---|

| Mold Calibration | Manual path adjustment | Perfectly centered LED placement. |

| Material Sync | Screw speed balancing | Zero “bleeding” in three-color strips. |

| Maintenance | Deep cleaning protocols | 30% longer mold life between services.99% perfect product output. |

| Troubleshooting | Error code resolution | Reduces unplanned downtime by 50%. |

I like hiking and playing basketball because they require stamina and focus. I bring that same energy to your factory. I have seen how a well-trained team in Saudi Arabia can outperform a larger factory that lacks technical guidance. It is not just about the machine; it is about the “unreplaceable advantage” of experience. I solve the cross-border technical service puzzles so you can focus on selling your products.

Can your LED silicone strip extrusion machine handle the “huge work” of material formulation and supply?

Are you worried about where to find the right silicone or additives in your local market? Finding a machine is easy, but maintaining a consistent supply of high-performance materials is where most international projects fail.

An LED silicone strip extrusion machine requires a precise material formulation, including the right base silicone and specific additives for UV resistance and diffusion. A total solution provider helps you source or formulate these materials locally or provides a seamless supply chain from China to guarantee continuous production.

This is a part of the business that many people forget. Shane might have a great idea for a new 1615 front-emitting strip, but if he doesn’t have the right “platinum-cured” silicone, the product will turn yellow in six months. I have spent years visiting different factories and learning the secrets of surface treatment and material science. I know that silicone from different factories has different performance. Some are better for medical tubes, and some are better for LED strips.

When I was in India, we had to find a way to use locally available additives to save on import taxes. This was “huge work.” We spent days testing the “cure rate” and the “Shore A” hardness. I used my experience in international business to help the client negotiate with local suppliers while I provided the technical “recipe.” This is a service you won’t get from a standard equipment seller. We provide a bridge between the material chemistry and the LED silicone strip extrusion machine settings. If the material changes, the machine must change too. I stay long enough to make sure that balance is perfect. Check out our material guidance for more details.

Why Material Consistency Matters in B2B

- Optical Clarity: The wrong additive will make the LED light look “muddy” or dim.

- Cure Speed: If the silicone cures too slowly, the strip will lose its 1615 rectangular shape before it cools.

- Adhesion: In three-color co-extrusion, the layers must “melt” together. Poor material choice leads to delamination.

I have a strong interest in economics and politics. I understand how supply chains are affected by global events. That is why I always have a “Plan B” for my clients. If they cannot buy the material in China, I help them find it elsewhere. I am not just selling a machine; I am ensuring your factory can run for the next 10 years without stopping. My goal is to make sure you have everything you need, from the first screw to the last kilogram of silicone.

Is manual mold modification the secret to perfect 1615 neon flex output?

Do you wonder why your competitors have perfectly crisp edges on their neon flex while yours look rounded and unprofessional? The difference is often found in the manual “tuning” of the extrusion mold paths.

Manual mold modification for an LED silicone strip extrusion machine involves fine-tuning the internal flow channels to compensate for material drag. This skilled process ensures that the silicone reaches the corners of the 1615 profile at the same time, creating sharp edges and a consistent surface finish for high-end lighting.

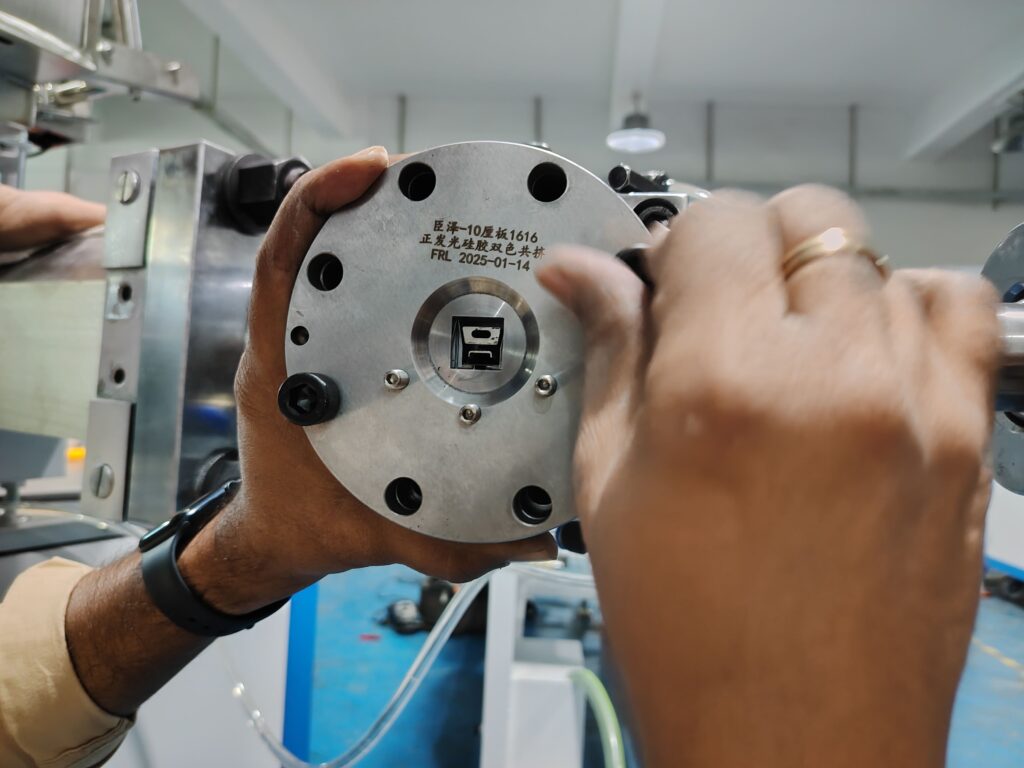

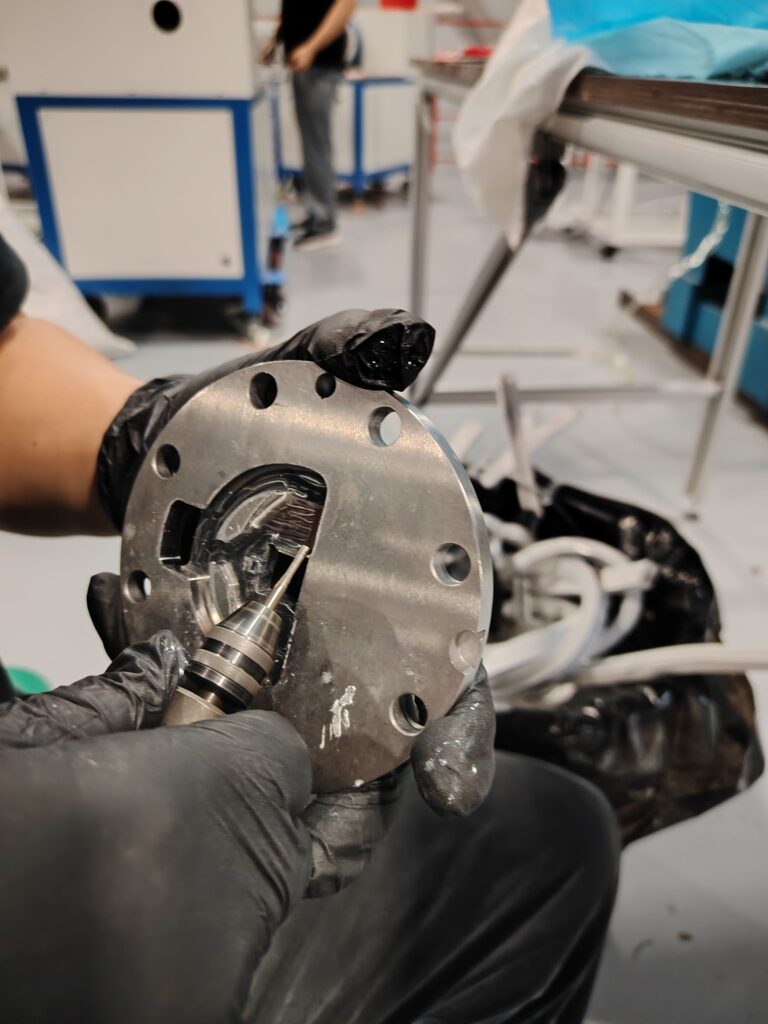

Look at the photo of our technician with the sanding tool. This is where the magic happens. A mold might look perfect on a CAD drawing, but silicone is a “living” material. It has friction. I have seen this in every country I have visited, from the Philippines to Iran. When we do the first test run of the LED silicone strip extrusion machine, we might see that the “1615” profile is slightly thicker at the bottom. I don’t just accept that. I use my experience in CNC and hardware processes to modify the mold on-site.

I teach my clients’ employees how to do this. It is a very important skill. I explain that the material is like water in a pipe. If you want it to go faster to one corner, you must “make it a bigger gap” to increase material feeding. I have seen David from India or Shane from America be amazed at how a small change with a sanding tool can fix a huge production problem. This is the difference between a “skilled engineer” and a “machine operator.” I stay at your factory until your staff can perform these modifications themselves. This creates a “productivity” that is built to last. You can explore our mold development process online.

The Value of On-site Mold Optimization

| Problem Observed | Mechanical Cause | Manual Solution |

|---|---|---|

| Rounded Corners | Material drag at edges | Sanding the corner paths for easier flow. |

| Thin Side Walls | Pressure imbalance | Restricting the center flow to push material to sides. |

| Surface Ripples | High friction in the die | Mirror polishing the exit aperture. |

| PCB Shifting | Inner core is too loose | Micro-adjusting the 12mm board slot. |

I like reading about history and visiting different factories because it shows me how techniques have evolved. In the old days, everything was manual. Today, we have the LED silicone strip extrusion machine and CNC, but the “human touch” is still what creates quality. I have two sons, and I want them to understand that technology is nothing without the skill to use it. When I leave your factory, I leave behind a team that knows how to perfect their own tools.

Why does a sales engineer with hardware and CNC experience save you more than a cheap machine?

Are you tempted by a lower price tag from a supplier who only knows how to send invoices? You might save $10,000 today, but you will lose $100,000 later when you cannot solve a technical bottleneck.

A sales engineer with CNC and hardware experience adds value to your LED silicone strip extrusion machine by providing deep technical insights into machine construction and mold design. This expertise allows for faster troubleshooting, better product customization, and a higher standard of equipment durability that a pure salesperson cannot offer.

I am not just a guy in a suit. I am a skilled engineer who knows how a CNC machine cuts a plate and how surface treatment affects the life of a screw. When I communicate a machine solution to an engineer like Shane, I am thinking about the final product function. If he wants a specific “neon light output,” I know exactly which mold configuration we need. I have been in this industry for more than 5 years, and I have seen every mistake that can be made. My experience of creating products means I can see problems before they happen.

I often tell my clients in Saudi Arabia or Russia that a LED silicone strip extrusion machine is an investment in a partnership. Because I know international business practices well, I can handle the logistics and the technical details at the same time. If you have a problem with a surface treatment technique on your final strip, I don’t tell you to “call the factory.” I solve it myself. I have interest in politics and economics, so I know that your factory needs to be efficient to survive in the global market. I provide the machine proposal and the quotation that are based on reality, not just on a sales target. Visit our about us page to see our factory.

The Benefits of a Technical Sales Partner

- Accurate Configuration: We choose the right screw and motor for your specific silicone viscosity.

- Speed of Response: Technical questions are answered in minutes, not days.

- Seamless Support: We handle the mold design, the machine build, and the on-site training.

- Product Realization: We help you turn a design drawing into a finished 1615 or 1212 strip.

I enjoy playing basketball because it is a fast game that requires quick thinking. The extrusion industry is the same. When a machine is down, every minute costs money. You need a partner who can solve problems at the speed of business. I bring my years of hiking and outdoor experience to my work—I am used to long hours and difficult conditions. Whether your factory is in a remote part of Vietnam or a busy city in Poland, I will be there to make sure your LED silicone strip extrusion machine is a success.

Conclusion

Mastering the LED silicone strip extrusion machine requires a combination of high-end hardware and expert on-site technical support to ensure your long-term success.