Are you struggling with uneven light output or material waste? Many factory owners buy expensive machines but fail to produce high-quality strips because they overlook the critical mold adjustment process.

To achieve perfect 1615 neon flex, you must synchronize your LED silicone strip extrusion machine with a precision-tuned three-color co-extrusion mold. Success depends on balancing the material flow through manual path optimization and maintaining strict temperature control to ensure seamless bonding between different silicone layers.

I have spent more than five years in this industry. I have visited factories in Russia, Saudi Arabia, and India to install these lines. I often tell my clients that the machine is the body, but the mold is the heart. If the heart is not right, the body will not perform. Let me share how we make these “hearts” work perfectly.

Why is precision mold design the secret to your LED silicone strip extrusion machine success?

Is your production line creating too much scrap material during start-up? Many engineers think that a machine with a famous brand name will solve everything, but the real magic happens in the tiny gaps of the extrusion die.

The secret to success with an LED silicone strip extrusion machine lies in the internal flow dynamics of the mold. A well-designed mold ensures that the silicone wraps around the LED strip evenly without creating air bubbles or mechanical stress that could damage the delicate internal electronics.

When I was training a team in Poland last year, we faced a big problem. The 1615 strip they were making had a slight curve. I used my experience with CNC processes to look at the mold plates. I realized the material path was too tight on one side. In this industry, we talk about “flow balance.” If the silicone moves faster on the left than the right, the strip will bend as it cools.

I have two sons, and I often compare mold design to teaching them how to walk. You have to guide the material gently. If you force it too hard through a narrow path, it resists. In my years of visiting different factories, I have seen that the best results come from molds that have been manually “tuned.” We use high-grade steel like S136H because it handles the pressure of the LED silicone strip extrusion machine without deforming.

| Feature | Impact on Production | Why it matters |

|---|---|---|

| High-grade S136H Steel | Long mold life | Prevents frequent downtime for mold replacement. |

| Mirror-polished paths | Smooth surface finish | Reduces friction and prevents silicone “scorching.” |

| Modular plate design | Easy cleaning | Allows for every day deep maintenance cycles. |

I always tell R&D engineers like David from India that they must provide very clear design drawings. If the LED strip size is 12mm, the mold core must account for the expansion of the silicone. If you don’t understand hardware processes and surface treatments, you will never get a smooth “neon” look. You will just get a piece of rubber with light inside it.

How does three-color co-extrusion technology differentiate your 1615 neon strips?

Are you tired of your competitors selling the same basic products as you? The market for LED lighting is very crowded, and the only way to win is to offer something they cannot easily copy, like high-end three-color co-extrusion.

Three-color co-extrusion technology allows an LED silicone strip extrusion machine to combine a transparent top layer, a white reflective base, and a colored side wall in one single pass. This creates a professional Neon Flex that has higher brightness and better color consistency than single-layer products.

This is where things get complicated. I remember working with a client in Saudi Arabia who wanted a very specific 1615 strip. They wanted a red base with a milky white diffuser. We had to connect three separate screw barrels to one single die head. This is what we call a “huge work” of synchronization. Every barrel on the LED silicone strip extrusion machine must have its own pressure sensor.

If the pressure in the white silicone barrel is higher than the red one, the white will push into the red section. You will see a messy line instead of a sharp, professional edge. I stayed at their factory for 10 days to train their staff. We worked on the “melt temperature” of the different silicones. Because I like reading about economics, I always explain to my customers that reducing waste in this stage is the fastest way to increase their profit margin.

The technical challenge of material fusion

When you use a three-color LED silicone strip extrusion machine, you are dealing with different “shore hardness” levels. Usually, the base is harder for support, and the top is softer for light diffusion.

- The fusion zone must be long enough for the silicones to bond.

- The temperature must be high enough to start the curing but not so high that it burns and damages LED chips.

- The speed of the machine must be consistent to avoid “pulsing” lines.

I have seen many engineers try to buy cheap machines to do this. It never works. You need a stable control system. I often tell David that if he buys the material locally in India, he must test the “viscosity” first. Different brands of silicone behave differently. I can provide the material formulation for my clients because I know every detail of how the additives affect the final output.

Why is manual mold modification a “must-have” skill for your engineers?

Do you think that a mold is finished once it leaves the CNC machine? If you do, you will likely struggle with production delays and low yield rates when you start your LED silicone strip extrusion machine.

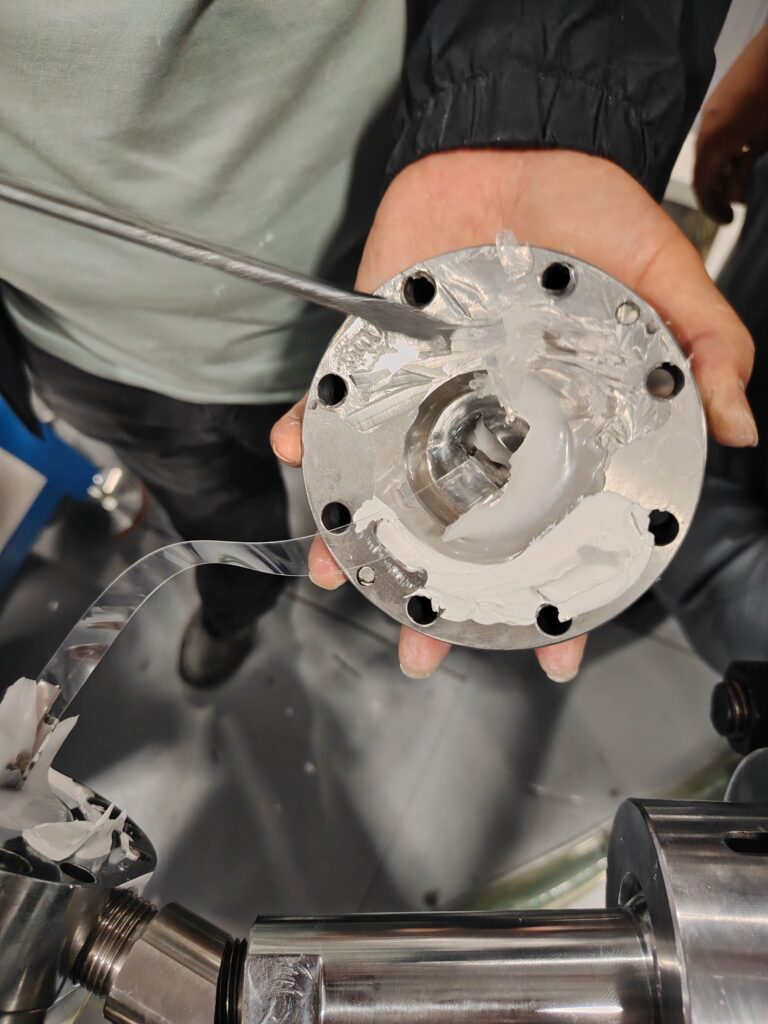

Manual mold modification, or “sanding the path,” is the process of fine-tuning the internal channels of an extrusion die to perfect the material flow. It is a critical skill that allows technicians to fix flow imbalances that cannot be predicted by computer simulations alone.

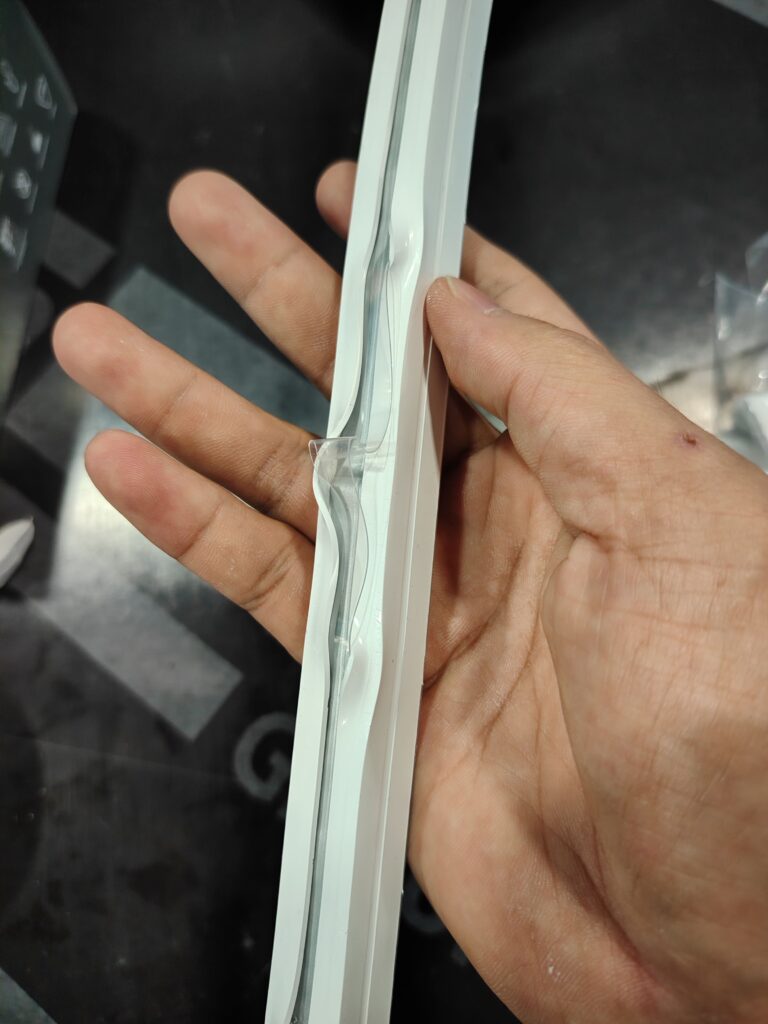

Look at the images I shared. You see a technician using a small sanding tool. This is a very precise job. He is making a gap slightly bigger to increase the material feeding. I have done this many times in factories in Vietnam and Russia. When we test the machine, we might find that one corner of the 1615 strip is not filling properly.

I use my knowledge of hardware processes to decide where to sand. If you remove too much metal, the mold is ruined. If you remove too little, the strip is still bad. This is why I stay at customer factories for 7 to 14 days. I don’t just turn on the machine. I train the employees on how to “feel” the flow. Once they master this, they can solve problems themselves. This makes their factory much more competitive in the local market.

| Modification Step | Purpose | Expected Result |

|---|---|---|

| Channel Widening | Increase local flow | Fills “thin” spots in the strip profile. |

| Edge Sharpening | Define corners | Creates the crisp 1615 rectangular shape. |

| Surface Polishing | Reduce drag | Prevents surface ripples on the neon flex. |

I really enjoy visiting different factories. It is like hiking a new trail. You never know exactly what the ground will be like until you are there. I take my experience from the CNC workshop and apply it to the extrusion line. If an R&D engineer like David provides me a design, I can immediately tell him if the material path will be a problem. This “pre-analysis” saves my customers thousands of dollars in wasted mold costs.

What are the common pitfalls in silicone material selection for your extrusion machine?

Are you choosing your silicone material based only on the lowest price? This is the most common mistake I see in the international business world, especially for factories just starting with an LED silicone strip extrusion machine.

The wrong silicone material can cause your extrusion machine to clog, lead to yellowing of the final product, or result in poor adhesion between colors. Choosing a material requires balancing the “cure rate,” “transparency,” and “thermal stability” to match the specific speed and heat of your production line.

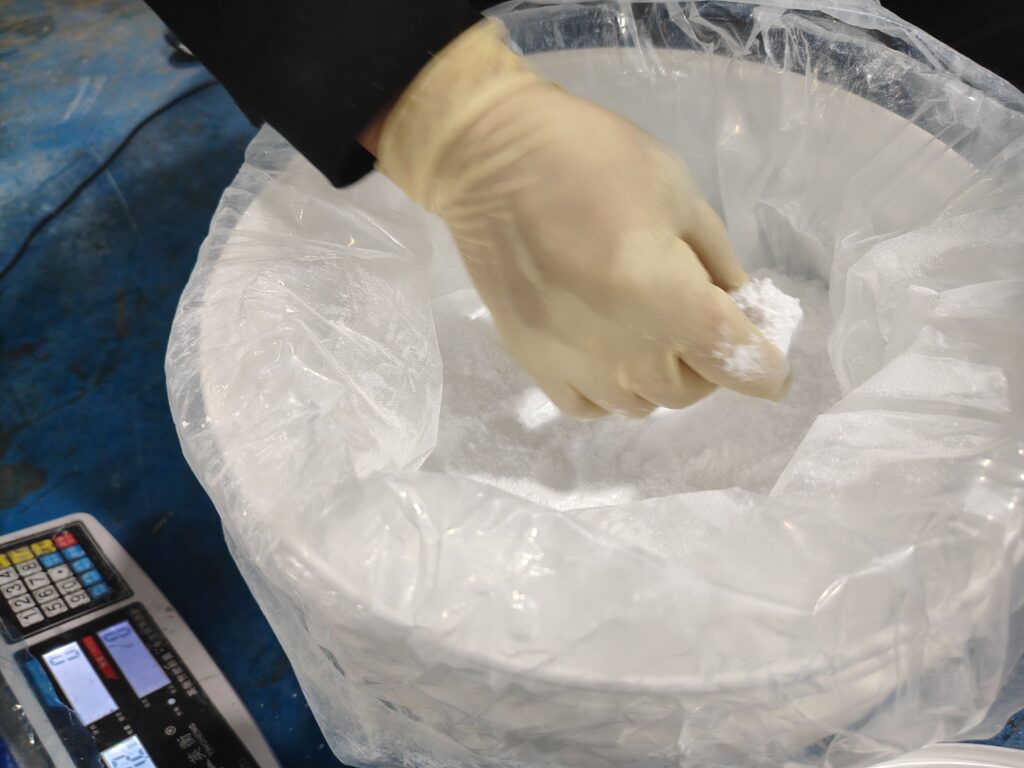

When I deal with customers in Iran or India, we often discuss the material formulation. Silicone is not just one thing. It is a mix of the base polymer, catalysts, and additives. If the cure rate is too fast, it will harden inside the LED silicone strip extrusion machine before it leaves the mold. I have seen barrels get stuck so hard that the motor burned out.

I like to play basketball, and I think of material selection like a team sport. The machine, the mold, and the silicone must all work together. If one is bad, the whole game is lost. David often asks me if he can buy material in India to save on shipping. I tell him yes, but he must let me check the data sheet first.

- Is the silicone “platinum-cured” or “peroxide-cured”? (Platinum is better for LED strips).

- What is the “Shore A” hardness? (Usually 60-70 for the base).

- Does it have UV stabilizers? (Essential for outdoor 1615 neon flex).

I provide a “seamless support” service. This means I help my clients find the right material suppliers. I don’t just sell the machine and leave. I know that their success depends on a steady supply of high-quality silicone. If they can’t stay in China to verify the suppliers, I do that work for them. It is a huge job to confirm every detail, but it is necessary for continuous production.

Why is on-site training the most important part of your equipment investment?

Do you think that an instruction manual is enough to run a complex LED silicone strip extrusion machine? Many people try to save money by skipping on-site training, only to realize later that they cannot produce a single salable meter of product.

On-site training by an experienced engineer is essential because it bridges the gap between theoretical machine operation and practical production reality. During 7-14 days of training, your team learns how to handle material fluctuations, perform emergency maintenance, and optimize the machine for local environmental conditions.

I have traveled to the Philippines and Saudi Arabia to lead these trainings. It is not just about pushing buttons. I teach the workers how to listen to the machine. A high-quality LED silicone strip extrusion machine has a specific sound when it is running perfectly. If the screw is struggling, the sound changes.

During my 7-14 days on-site, I focus on:

- Safety protocols: These machines use high heat and pressure.

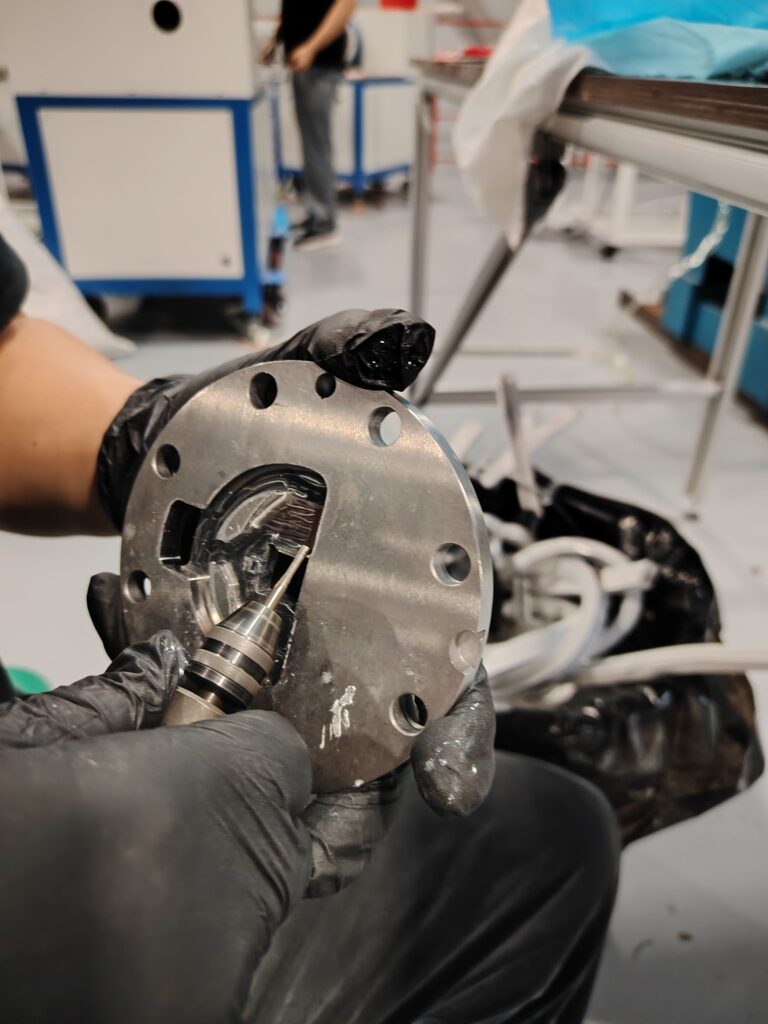

- Mold disassembly: Showing them how to clean the 1615 mold without scratching the surface.

- Speed optimization: Finding the “sweet spot” where the machine runs fast but the quality stays high.

I remember a factory in Russia where the temperature in the workshop was very cold. This affected the silicone flow. We had to adjust the heater bands on the LED silicone strip extrusion machine to compensate. A manual wouldn’t tell you that. Only experience can. By the time I left, the local team was confident. They weren’t just “operators” anymore; they were “technicians.” This is how you build a lasting business. I have two sons, and I want them to grow up knowing that their father builds things that last.

How to maintain your LED silicone strip extrusion machine for 24/7 production?

Is your machine sitting idle because of a small part that broke or a mold that is clogged? In the B2B world, downtime is the enemy of profit. You need a maintenance plan that is as robust as the machine itself.

Maintaining an LED silicone strip extrusion machine requires daily cleaning of the die head, weekly inspection of the heater bands, and monthly lubrication of the drive system. A strict cleaning schedule for the three-color co-extrusion mold prevents material buildup and ensures the long-term optical clarity of your neon flex.

When we disassemble a mold, like the one in the photos, we must be very careful. Use only soft tools to remove the cured silicone. If you use a steel screwdriver, you might scratch the “mirror” finish inside the path. Once that happens, every strip you make will have a visible line on it. I teach this in every training session I lead.

I also emphasize the “pre-check” before every shift. Check the vacuum pump. Check the water cooling levels. The LED silicone strip extrusion machine is a precision instrument. I have experience with surface treatment and hardware, so I know how quickly metal can degrade if it is not cared for.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Mold Cleaning | Every Shift End | Prevents “burnt” silicone spots. |

| Screw Inspection | Every 3 Months | Checks for wear that affects pressure. |

| Electrical Cabinet Dusting | Monthly | Prevents short circuits in the PLC system. |

I am very interested in politics and economics, and I see how global supply chains are changing. Having a machine that is easy to maintain is a huge competitive advantage. If you can fix your own mold and keep your line running while your neighbor is waiting for a technician from China, you win the market. That is why I provide all the tools and training necessary for my clients to be independent.

Conclusion

Success in LED strip production requires the right machine, the right mold, and the right training. By focusing on precision and professional support, you can dominate your local market.