Mastering Precision: A Deep Dive into LED Silicone Strip Extrusion Machine Mold Design and Three-Color Co-extrusion

In the high-stakes world of architectural lighting manufacturing, the LED silicone strip extrusion machine stands as the ultimate tool for producing premium Neon Flex. While many manufacturers focus solely on the speed of the motor or the length of the cooling tank, true industry veterans know that the “soul” of the machine resides in the extrusion mold.

To produce a market-leading product, such as the 1615 front-emitting three-color co-extrusion strip, a factory must master the delicate balance between automated power and manual precision engineering. This guide utilizes first-hand technical data and workshop insights to explore the intricacies of mold design and process optimization.

The Evolution of the LED Silicone Strip Extrusion Machine

The transition from PVC to silicone in the LED industry has revolutionized the longevity and flexibility of linear lighting. However, the LED silicone strip extrusion machine must navigate much more complex material properties than its plastic-predecessor. Silicone is a thermosetting polymer with specific rheological behaviors that require precise thermal management and pressure control.

Modern high-end machines are no longer simple single-material lines. They have evolved into complex systems capable of “co-extrusion,” where multiple types of silicone—such as high-transparency, diffusion-white, and structural-base layers—are fused into a single seamless profile in real-time.

Analyzing the 1615 Three-Color Co-extrusion Mold

A cornerstone of professional-grade production is the specialized mold. In the context of the LED silicone strip extrusion machine, the mold dictates the final dimensions, light distribution, and aesthetic finish of the strip.

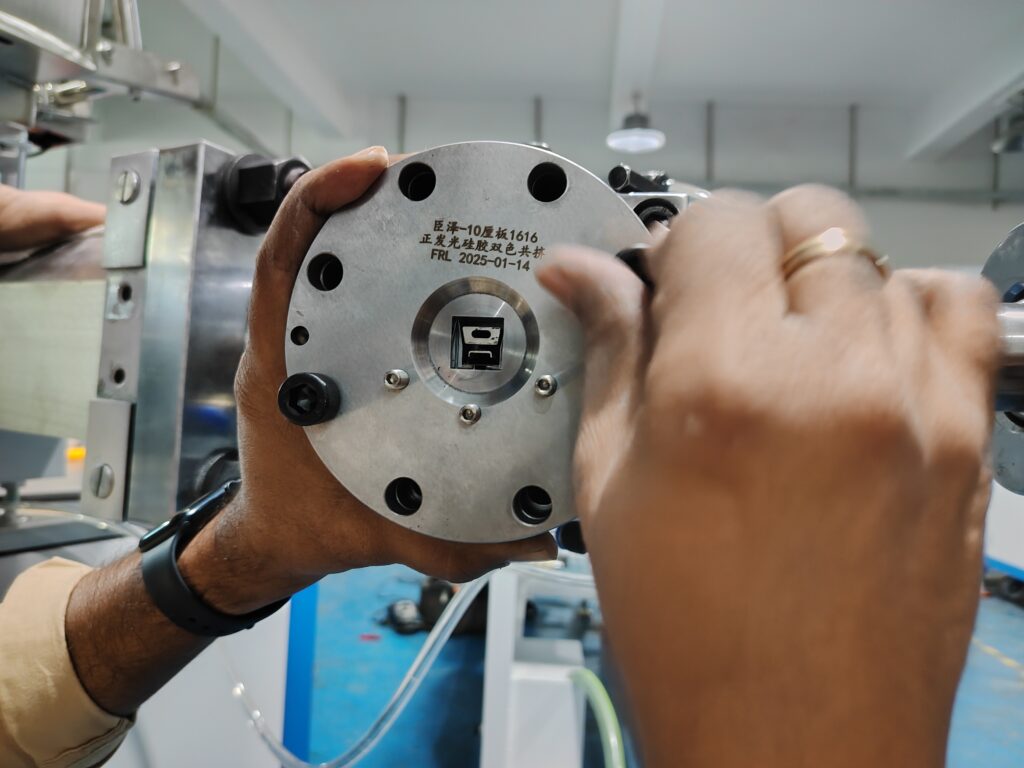

As seen in our engineering records, a specialized mold was developed for the “Chenze-12mm Board 1615 Front-emitting Three-color Co-extrusion” dated April 22, 2025. This specific “1615” designation refers to a 16mm x 15mm cross-section, which is a global standard for facade and decorative lighting.

Key technical aspects of this mold include:

- Front-Emitting Precision: The output aperture is engineered to ensure the light is thrown forward with a 180-degree beam angle.

- Three-Color Integration: The mold features three distinct input ports to allow three different silicone compounds to meet at the extrusion point.

- Structural Integrity: The core mold is designed to house a 12mm wide LED PCB, ensuring a snug fit that prevents the internal strip from shifting during installation.

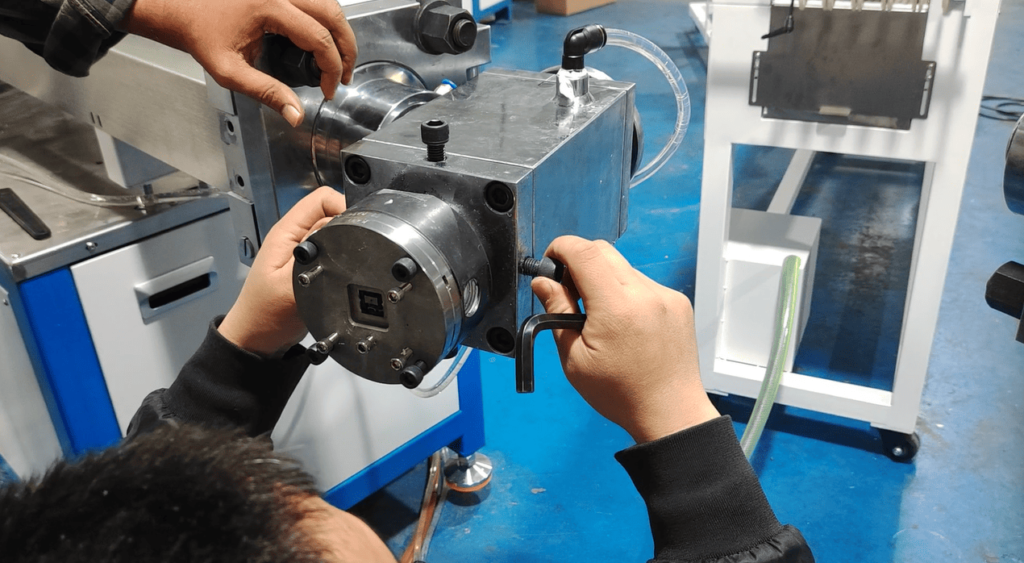

The Critical Role of Manual Mold Modification

One of the most significant “industry secrets” in the operation of an LED silicone strip extrusion machine is that the mold often requires manual fine-tuning to achieve perfection. Even the most advanced CNC-machined mold may need adjustments based on the specific batch of silicone being used.

Our workshop data shows a technician using a high-speed sanding tool to modify the inner mold material path. This is not a correction of a defect, but rather a sophisticated optimization of the flow dynamics.

- Widening the Feed Gap: By manually increasing the gap in certain material paths, the technician increases the material feeding rate to specific sections of the 1615 profile.

- Flow Equalization: In three-color co-extrusion, different silicones have different viscosities. Manual sanding allows the technician to ensure that the white reflective layer and the transparent outer jacket reach the exit point at the exact same pressure, preventing “bleeding” or uneven edges.

Internal Flow Path and Pressure Balancing

The complexity of the LED silicone strip extrusion machine is best visualized when looking at the internal cross-section of the mold. The internal material paths resemble a complex network of highways.

When the machine is running, the silicone must be forced through these channels without creating air pockets or “dead zones.”

- Center Output: The central square-like aperture is where the primary shape is formed.

- Venting and Pressure: The layout of the bolt holes and the plate interfaces must be perfectly sealed. Any slight misalignment can cause a pressure drop, leading to “waviness” in the final 1615 strip.

- Material Path Design: The internal paths are polished to a mirror finish to reduce friction, which otherwise would generate localized heat and pre-maturely cure the silicone.

Maintenance Protocols: Disassembly and Cleaning

For any operator of an LED silicone strip extrusion machine, maintenance is the difference between a machine that lasts 10 years and one that fails in two. Because silicone cures and hardens over time, the mold must be disassembled regularly.

The disassembly process involves separating the multi-layered plates that make up the co-extrusion head. This allows the team to:

- Remove Residue: Technicians must carefully scrape away residual silicone that has adhered to the inner flow channels.

- Inspect for Wear: High-pressure extrusion can eventually wear down the edges of the inner mold. Regular inspection ensures the 1615 dimensions remain within tolerance.

- Ensure Clean Boundaries: In three-color systems, the “junction points” where colors meet must be perfectly clean. If even a small amount of old silicone remains, it can contaminate the color purity of the next production run.

Industry Benchmarks for 2026 Production

As we look toward 2026, the requirements for the LED silicone strip extrusion machine market are becoming stricter. Buyers are no longer satisfied with “good enough”; they require documented performance. Based on our 2025 mold data, we recommend the following production benchmarks:

| Parameter | High-Performance Target | Impact on B2B Success |

| Co-extrusion Speed | 10 – 15 Meters/Minute | Higher throughput reduces cost per meter. |

| Color Separation | < 0.05mm Bleed Line | Essential for high-end “Neon” aesthetics. |

| Scrap Rate | Less than 2% per run | Direct impact on factory profit margins. |

| Mold Steel Grade | S136 (Hardened) | Extends mold life for long-term 24/7 production. |

Choosing a Technical Partner for Extrusion Success

In the international B2B landscape, the machine is the hardware, but the engineering support is the “software” that makes it work. When selecting an LED silicone strip extrusion machine provider, you must ensure they have the capability to customize molds for specific profiles like the 1615 or 1212.

The ability to provide first-hand data, detailed disassembly guides, and evidence of manual optimization is what separates a world-class supplier from a middleman. By focusing on the precision of the mold, you ensure that your production line is capable of producing the most demanding lighting designs of the future.

- Hidden Cost Analysis: 5 Ways a Low-Price Silicone Extruder Will Kill Your Factory Profits in 2026

- 2026 Maintenance Guide: How to Extend the Life of Your High-Precision Silicone Extrusion Molds

- 2026 LED Silicone Extrusion Industry Trends: The Perfect Fusion of COB LED Strips and Silicone Sleeves

- Why is the mold the heart of your LED silicone strip extrusion machine success?

- 5 Key Differences Between Silicone and PVC Extrusion Machines: Why Your Factory Must Switch to Silicone in 2026