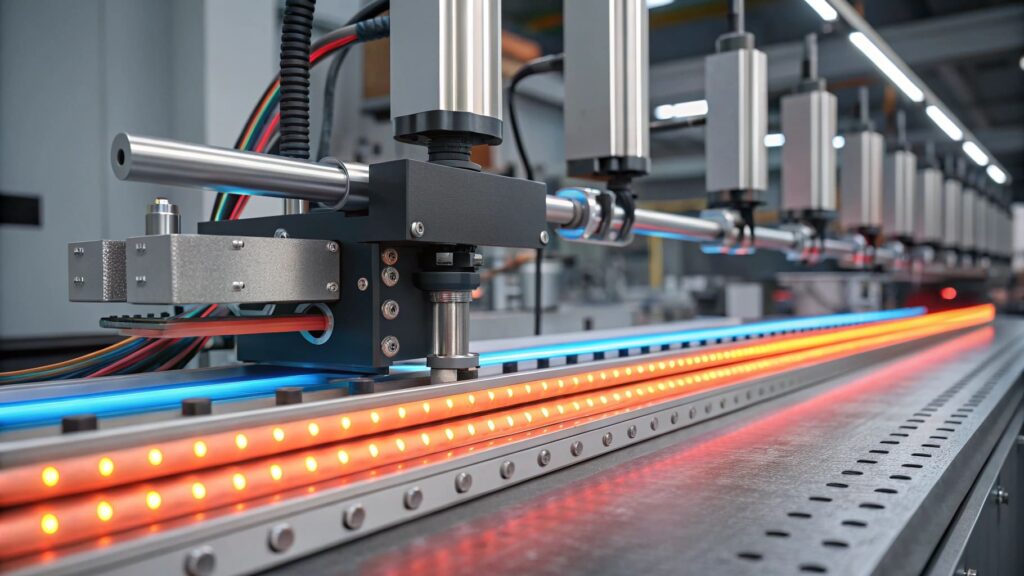

LED extrusion is the process of shaping silicone material to encase LED strips. It protects the LEDs while enhancing their appearance, durability, and functionality.

LED extrusion ensures uniform light diffusion and strong protection for LED strips, making them suitable for diverse applications, including lighting and decoration.

LED extrusion plays a critical role in LED strip production. Understanding its process and equipment will help you choose the right solution for your needs. Let’s dive deeper into key considerations.

How to choose a silicon extrusion production line?

Choosing the right silicon extrusion production line is critical. It impacts production efficiency, product quality, and cost.

You must determine the type of LED strip you want to produce. Single-color extrusion requires one extruder machine, while two-color or three-color extrusion needs more.

Key Steps to Choose the Right Line

- Identify the Strip Type:

- Single-color LED strip: One extruder machine.

- Two-color LED strip: Two extruder machines.

- Three-color LED strip: Three extruder machines. Different configurations allow different designs and outputs.

- Evaluate Your Facility:

- Minimum space requirement: 35m x 5m.

- Workforce: 5 trained workers per shift.

- Material Considerations:

- Silicone material, curing agents, and color masterbatches.

- Consider whether to source locally or through our competitive supply chain.

- Logistics and Installation:

- Production time: 35 working days.

- Shipping: One 40′ container, taking 10–35 days by sea.

- Training: On-site or at our factory.

Each setup varies in cost and complexity. We guide you through material choices, machine configurations, and training to ensure seamless production.

How do you solder LED strips?

Soldering LED strips is essential for creating secure connections between sections.

Soldering LED strips involves heating solder to connect electrical contacts securely. It ensures proper function and minimizes voltage drops.

A Step-by-Step Guide to Soldering

- Prepare Tools and Materials:

- Soldering iron (30-40W recommended) or automatic soldering machine.

- Solder wire and flux.

- Heat shrink tubing or electrical tape.

- Cut and Position Strips:

- Cut LED strips at marked points.

- Align copper contacts correctly.

- Apply Solder:

- Heat the soldering iron.

- Apply a small amount of solder to the contacts.

- Join wires to the strip, ensuring polarity matches.

- Secure Connections:

- Use heat shrink tubing for insulation.

- Test connections before installation.

Proper soldering techniques ensure durability and stable electrical performance.

Do LED strips use a lot of electricity?

LED strips are energy-efficient, making them a cost-effective lighting choice.

LED strips consume far less electricity compared to traditional lighting. Power usage depends on strip type and length but remains low overall.

Understanding Power Consumption

- Wattage and Voltage:

- LED strips typically use 12V or 24V systems.

- Power consumption ranges from 4W to 20W per meter.

- Efficiency:

- LEDs convert most energy into light with minimal heat.

- Ideal for long-term use with reduced energy bills.

- Usage Scenarios:

- Accent lighting consumes less power.

- Continuous lighting may slightly increase energy use but remains efficient.

LED strips offer excellent brightness while keeping energy consumption low, saving costs over time.

What material is a LED strip made of?

LED strips consist of various materials that provide flexibility, durability, and optimal light diffusion.

LED strips are made of flexible PCBs, LED chips, silicone, adhesives, and optional protective coatings for durability.

Material Composition of LED Strips

- Flexible PCB (Printed Circuit Board):

- The backbone of the strip, holding LED chips and circuit connections.

- Offers flexibility for versatile installations.

- LED Chips:

- High-brightness light-emitting diodes.

- Available in single-color, multi-color, or RGB options.

- Silicone or Epoxy Coating:

- Protects LEDs from moisture, dust, and impact.

- Enhances light diffusion for uniform brightness.

- Adhesive Backing:

- Provides easy installation on various surfaces.

- Ensures strips stay in place.

- Optional Components:

- Heat sinks for high-power strips.

- Reflective layers for better light direction.

High-quality materials ensure LED strips are reliable, efficient, and long-lasting.

Conclusion

LED extrusion and related processes are essential for high-quality LED strip production. From choosing the right production line to understanding materials and energy efficiency, each step contributes to better results. Let’s work together to create the perfect solution for your needs.