When looking for an LED strip silicon extrusion machine manufacturer[^1], the key is understanding your needs. The right manufacturer can make your production efficient and cost-effective.

Finding a reliable LED strip silicon extrusion machine manufacturer involves determining your production requirements, researching suppliers, and comparing solutions. Focus on quality, customization, and post-purchase support.

[^1]: Exploring this link will provide insights into selecting a manufacturer that ensures efficiency and cost-effectiveness in production.

Choosing the right machine is not just about the product but also about the service and support the manufacturer offers. Let’s dive deeper into key considerations.

What is the best brand of LED light strips?

Finding the best LED light strip brand depends on your specific requirements and market.

The best brand for LED light strips combines quality, durability, and affordability. Factors like brightness, power efficiency, and lifespan also play a significant role in determining the right choice.

Identifying the Best Brand

LED light strips are diverse. Brands like Philips Hue and GE Lighting are known for high-quality, reliable strips. For cost-conscious buyers, lesser-known brands may provide value. Compare brightness (measured in lumens)[^1], color accuracy (CRI rating)[^2], and wattage[^3]. Different markets prioritize different features. Researching your target audience can help identify the best fit.

[^1]: Understanding how brightness is measured can help you choose the right LED light strip for your needs, ensuring optimal lighting for any space.

[^2]: Exploring the importance of CRI rating will guide you in selecting LED light strips that offer the best color accuracy, enhancing the ambiance of your environment.

[^3]: Learning about wattage’s impact on LED light strips can help you make energy-efficient choices, saving on electricity bills while achieving desired lighting effects.

Quick Comparison Table:

| Feature | High-End Brands | Budget Brands |

|---|---|---|

| Brightness | High (800+ lumens) | Moderate (300-700) |

| Color Accuracy (CRI) | Excellent (90+) | Average (70-80) |

| Lifespan | 50,000+ hours | 20,000-30,000 hours |

| Cost | Premium pricing | Affordable |

Knowing the brand that matches your quality and cost expectations will guide your material selection.

What material is a LED strip made of?

LED strips are made of several key materials that contribute to their functionality and durability.

A standard LED strip consists of a flexible PCB base, light-emitting diodes, resistors, and an adhesive backing. For durability, silicone is often used for encapsulation and waterproofing.

Understanding Materials

Flexible PCBs[^1] form the backbone of LED strips. Copper is the primary conductor[^2], laminated with an insulating layer. The diodes determine brightness and color. Encapsulation, often silicone or epoxy[^3], adds waterproofing and heat resistance. Choose high-quality silicone for durability and transparency, especially for outdoor applications. Resistors regulate voltage, ensuring long-lasting performance.

[^1]: Understanding the role of Flexible PCBs in LED strips can help you make informed decisions for your lighting projects, ensuring durability and efficiency.

[^2]: Exploring why copper is preferred as a conductor in LED strips can enhance your knowledge on material selection for better performance and longevity.

[^3]: Learning about the differences between silicone and epoxy encapsulation can guide you in choosing the right material for waterproofing and heat resistance in LED applications.

Material Breakdown:

| Component | Material Used | Function |

|---|---|---|

| PCB Base | Copper, Insulation | Conducts power |

| Encapsulation | Silicone/Epoxy | Waterproofing, heat resistance |

| LEDs | Semiconductor Diodes | Light emission |

| Adhesive Backing | High-quality Adhesive | Easy installation |

Understanding these materials helps in selecting the right extrusion machine and compatible components.

How to create a LED strip?

Creating an LED strip requires the right materials, equipment, and expertise.

LED strips are manufactured by assembling PCBs, attaching LEDs and resistors, and encapsulating the assembly in protective silicone. This process requires precision and high-quality machines.

The LED Strip Manufacturing Process

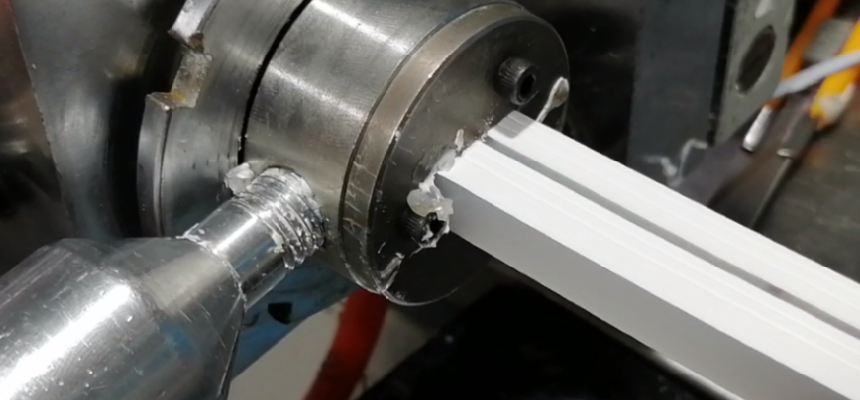

Producing LED strips starts with sourcing PCBs and components[^1] like LEDs and resistors. The PCB is printed with conductive traces, and components are placed using SMT machines. Encapsulation involves silicone extrusion[^2], which protects the strip and ensures flexibility. Machines like extruders and curing ovens are essential. Planning the strip type, such as single or multi-color, determines the extrusion configuration[^3].

[^1]: Exploring the latest trends can help you find cost-effective and high-quality materials for LED strip production.

[^2]: Understanding silicone extrusion can enhance your knowledge on protecting LED strips and ensuring their longevity.

[^3]: Learning about extrusion configuration factors can optimize your LED strip production for various applications.

Typical Production Setup:

| Step | Equipment Needed | Output |

|---|---|---|

| PCB Assembly | SMT Machines | Assembled PCB |

| Component Placement | SMT Lines | LEDs and Resistors Attached |

| Encapsulation | Silicone Extruder | Finished LED Strip |

Efficient production depends on the integration of materials and machines, tailored to your specific needs.

Is it safe to put LED strips on metal?

Yes, it is safe to install LED strips on metal surfaces if proper precautions are taken.

To safely use LED strips on metal, ensure the strip has adequate insulation and consider using heat-resistant adhesive or mounting channels to prevent overheating or short circuits.

Ensuring Safety with Metal Installations

Metal is an excellent conductor of heat, making it suitable for LED strips if used correctly. Always use insulated LED strips[^1] to avoid electrical shorts. Silicone or plastic mounting channels are highly recommended. They act as a barrier between the strip and the metal, preventing heat buildup and ensuring safety. Test the setup for stability and check local safety guidelines[^2].

[^1]: Learn the importance of insulation in LED strips to prevent electrical shorts and ensure safety in your lighting projects.

[^2]: Ensure your LED strip setup complies with local safety standards by exploring the latest guidelines and recommendations.

Tips for Installation:

- Use insulated strips or adhesive backing.

- Add thermal paste or heat-resistant adhesive for better heat dissipation.

- Employ mounting channels for additional safety.

- Avoid sharp edges or conductive surfaces that could damage the strip.

Following these steps ensures both functionality and safety for metal installations.

Conclusion

Finding the right LED strip silicon extrusion machine manufacturer starts with understanding your production goals and needs. With proper planning, material selection, and support, your production can achieve unparalleled efficiency and quality.